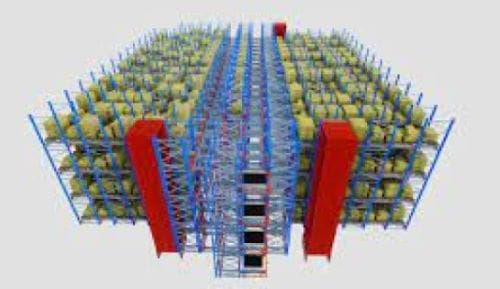

Semi Automated Pallet

SEMI-AUTOMATED HIGH DENSITY PALLET SHUTTLES

Semi-automated, high-density, pallet shuttle systems maximize the use of warehouse space and increase the selectivity and efficiency of your operation. The system increases productivity and reduces the risk of product and equipment damage and maintenance costs, making it a cost-effective storage solution.

Easily operated with a remote control, the system executes orders to load or unload pallets into a lane. The lanes are fed pallets by lift trucks such as reach trucks or counterbalanced forklifts.

-

FEATURES & BENEFITS

Semi-automated pallet shuttle systems save operating costs and warehouse space:

+ More pallets stored per lane

+ Less operator travel resulting in more pallets moved

+ Increased inflow and outflow of goods

+ Reduced operating costs

+ Fewer incidents of product, rack and equipment damage

+ System is easily controlled from a single tablet

+ Operates in all temperature zones

-

APPLICATIONS

Applications with mulitple pallets of storage for each SKU, including:

+ High volume SKU's

+ The first point of storage after manufacturing

+ Work in process

+ Product being held for quality testing

+ Sites with high product turnover (greater than 5 times per year)

+ Facilities running out of space

+ Storage layouts where deep lane storage is the best option

EQUIPMENT TO KEEP YOUR SYSTEM UP AND RUNNING

-

Rack Structure

The rack system aids the operator in loading shuttle units into the structure and guides pallets into the first position. -

Charging Station

Re-charge the batteries by placing both battery cassettes into the pull-out drawer, which automatically connects the batteries to power.

Contact Us

Contact us today to learn more about our pallet storage systems and other automated solutions