Material Handling Blog

Lift Trucks & Parts

-

Enhancing Workplace Safety with Blue Safety Lights for Forklifts

Discover how blue safety lights on forklifts are revolutionizing workplace safety by enhancing visibility and reducing accidents in high-traffic industrial environments. -

How To Determine Your Forklift Capacity When Adding New Attachments

If you’re in the market for forklift attachments, finding the right attachment for your capacity requirements can be a little bit confusing. Here's how to do it. -

Extend The Capabilities Of Your Forklift With Attachments

Your forklift is not just for lifting pallets! It’s a versatile piece of equipment that can be used for many types of tasks with the right accessories. -

Raymond Cold Storage Solutions

Maintaining operations in a refrigerated warehouse or freezer can be difficult on both personnel and equipment. Raymond offers ideal solutions for cold storage facilities. -

When Do Lift Truck Forks Need to be Replaced?

Ongoing use (or misuse) can cause wear, cracks and bends to your lift truck forks. Here's how to conduct a thorough inspection and determine when forks need to be replaced. -

Five Reasons You Should Be Using the Raymond Parts Department

Did you know the Raymond West Parts Departments stock parts for just about everything in your warehouse? Learn more about our Parts Programs. -

Adding Automated Guided Vehicles to Your Operation - Considerations

Are you thinking about making the jump to Automated Guided Vehicle (AGV) systems for your warehouse or distribution center? Here are a few things to consider. -

Everything you need to know about the Raymond ReNewed Program

Used lift trucks are a great option for many businesses. Get the lowdown on our used truck programs and the benefits they provide. -

Electric vs Propane: Which Forklift Is Right For Your Business?

One of the most basic factors to consider when buying a lift truck is how it is powered. Should you buy gas, diesel, propane or electric? -

Raymond High Capacity Reach Trucks Are The Best In The Business. Here’s The Proof.

In an independent performance study, Raymond’s 7530 High Capacity Reach Fork Truck was put to the test against its main competition, the Crown RMD 6092. The results speak for themselves. -

Safety Tip: Double Check Your Capacity Ratings

All forklifts have a maximum stated capacity. That number can change based on how your truck is equipped and how it is used. Learn how capacity ratings are calculated and what you need to know to maximize safety. -

Raymond’s “Safety On The Move” Forklift Safety Training

Raymond’s forklift operator training program has helped employers protect their people, equipment, and materials since its inception almost 30 years ago. -

Changing The Training Game With Virtual Reality

To address critical labor shortages, manufacturers are collaborating with technology companies to create virtual reality (VR) simulators that can be used as educational tools to help attract new generations. -

Raymond’s 8000 Series Electric Pallet Jacks Offer An Exceptionally Low Cost of Ownership

Raymond’s 8000 Series pallet trucks are designed to lower your total cost of ownership by minimizing downtime and reducing your maintenance costs. -

The Raymond 8610 Tow Tractor: A Powerful And Dependable Workhorse

If you’re looking for an ultra-rugged, high performance tugger, the Raymond 8610 is an ideal choice. -

4 Signs It’s Time To Introduce AGVs To Your DC Operation

AGVs can reduce demand on your existing equipment and free up labor hours for more complex tasks while automating routine horizontal transport jobs. -

Raymond Sideloaders: The Right Equipment For Long Loads

Raymond offers two different sideloaders, depending on your requirements and the configuration of your storage operation. -

Our Top 5 Forklift Safety Tips

Each year, there are roughly 62,000 forklift accidents in the United States. More than half of those result in serious injury. Forklift safety should be a number one priority for everyone that works in a warehouse. -

Everything You Ever Wanted To Know About Pallet Jack Wheels

What do you need to consider when replacing the wheels on your pallet jack? -

Some Tips On Preventing Forklift Accidents

The National Institute for Occupational Safety and Health (NIOSH) suggests the following key safety practices in their Publication 2000-112. -

18 Types Of Specialty Forks For Your Forklift

For some applications, specialized lift truck forks can make your job easier, safer and more efficient. -

Ensuring Pedestrian Safety In Your Warehouse

Crucial steps employers and forklift operators can take to ensure pedestrian safety in a warehouse environment, include the use of audible and visible warnings, physical separation, employee training, and personal protective equipment. -

Raymond West Adds Cruise Car To Its Electric Utility Vehicle Lineup

Discover a range of sleek, advanced, low-maintenance, and eco-friendly electric utility vehicles through the partnership between Cruise Car and Raymond West. -

Specialty Manual Pallet Jacks and Their Unique Applications

Learn about specialized manual pallet jacks and their diverse applications, from clean room options to heavy duty industrial uses. -

Raymond Introduces Electric Forklifts Designed for Outdoor Use

The Raymond Corporation has introduced its first electric forklifts designed for outdoor use. -

A Simple Guide to Powered Industrial Truck Classifications

Learn about OSHA's powered industrial truck classifications and find the perfect forklift for your specific operational needs. -

The Importance of Forklift Pedestrian Safety Training

Nearly 20% of reported forklift incidents involve pedestrians. Proper training can prevent injuries and save lives. -

Chain Inspection

Regular inspection and maintenance of forklift chains can help prevent accidents and prolong the life of your lift truck -

Forklift Accidents

Proper response to forklift incidents can minimize injury, reduce downtime, and ensure regulatory compliance.

Power Systems

-

Powering Progress: Navigating the Choice Between Lead Acid, Lithium-Ion, and Hydrogen Fuel Cells for Raymond Electric Forklifts

Compare lead acid, lithium-ion, and hydrogen fuel cells to find the best power source for your Raymond electric forklifts and boost efficiency, uptime, and ROI. -

The Power of Lithium-Ion: Raymond's Revolutionary Battery Solution

Raymond’s modern lithium-ion batteries offer our customers a power solution that not only meets their operational needs but also enhances efficiency and productivity. -

Is Lithium-Ion Right For Your Fleet? Use Raymond’s New ROI Calculator To Find Out

Our new 24v and 36v lithium ion batteries are designed to seamlessly integrate into your lift trucks, providing advanced data insights and wireless communication for remote diagnostics and upgrades. -

Making The Jump From Lead Acid to Lithium Ion – What To Expect

Lithium ion batteries can reduce your operational costs, improve efficiency and even enhance safety at your facility. But all of those benefits come with a catch—buying lithium ion batteries is quite a bit more expensive than going with traditional lead acid batteries. Here’s what to expect if you do switch battery technologies. -

Are lithium-ion batteries safe to use in your warehouse? Look at the UL marks.

Lithium-ion batteries are slowly but surely finding their place in today's warehouses. Learn about the differences by understanding UL ratings. -

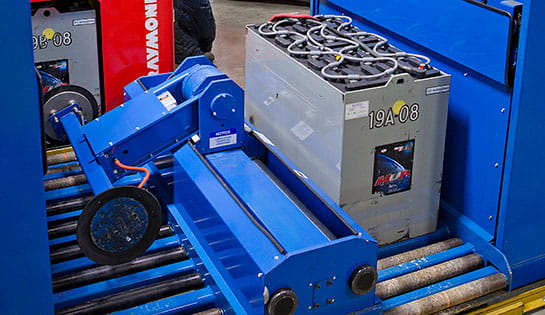

Small Changes in Battery Management Can Add Up To Big Savings

In many operations, practicing good battery management is often the exception rather than the rule. Smart battery management can identify problems and save you significant amounts of money. Learn the basics, and get on the path to operational savings. -

Avoid Damaging Batteries On Lift Tucks Taken Out Of Service During Covid 19

Preparing forklift batteries for long term storage of more than a few weeks can help you avoid costly repair or replacement down the road. Keep your batteries in top shape and ready to go back online when needed with these simple tips. -

10 Tips For Industrial Battery Handling Safety

Safety should be your top priority when managing industrial batteries. Review these 10 guidelines to keep you and your employees out of harm’s way. -

What Type Of Battery Charging Is Best For Your Operation?

Learn about the three main types of forklift battery charging systems - conventional, opportunity, and fast charging - and their pros and cons for cost, downtime, and battery life. -

Some Simple Tips To Extend The Life Of Your Forklift Batteries

Extend the life of your forklift battery with these key maintenance tips from Raymond West's battery experts, including proper watering, charging practices, and cleaning. -

Optimize your Electric Forklift Battery Life with Battery Watering

Maximize your electric forklift battery life. Learn proper watering, safety, and when to water in this essential guide for longevity and performance. -

Battery Recycling

Forklift battery disposal requires sustainable practices to prevent environmental and safety risks. From certified recycling partnerships to safe handling procedures, responsible disposal ensures compliance, minimizes hazards, and supports corporate sustainability goals.

Automated Storage Solutions

-

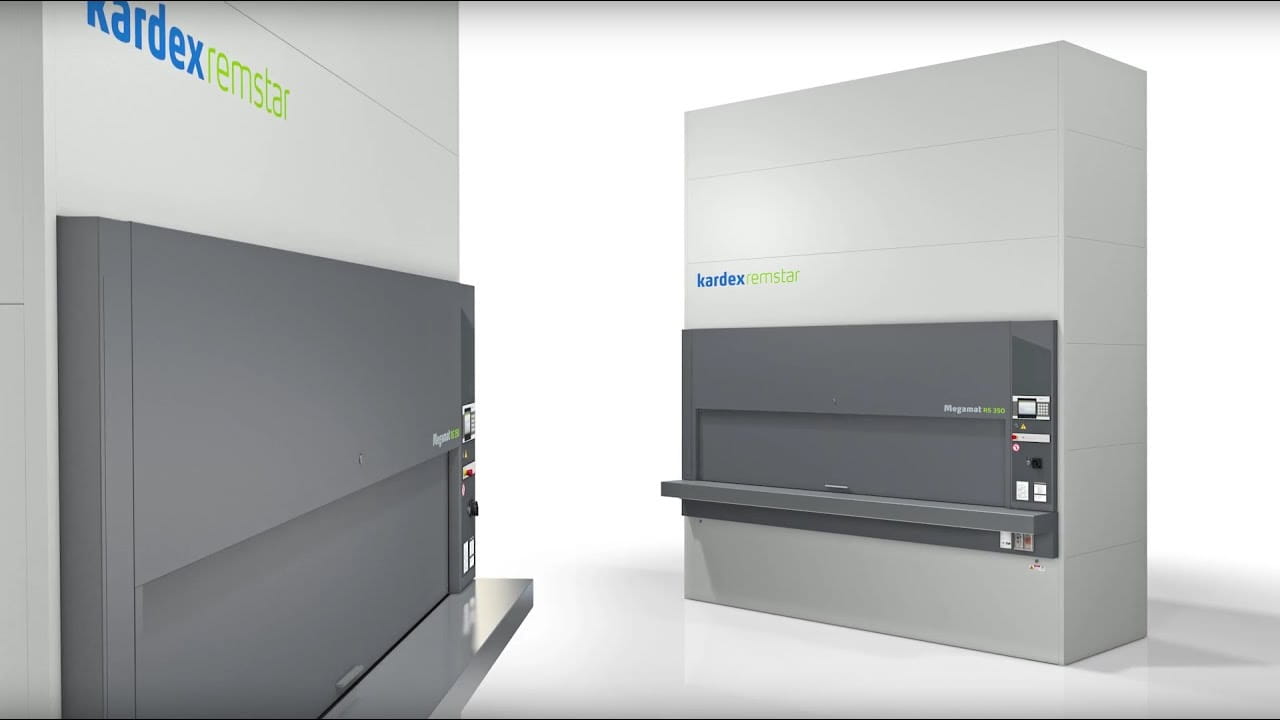

.jpg?rev=64c45e85c78040a69f277dcc16ebab5d&la=en&h=315&w=545&hash=D1EF71720237663F1B5D051AFB204D3F)

Why Your E-Com Operation Needs Goods-to-Person Technology

With the unprecedented growth of e-commerce, goods-to-person technologies help bridge the gap between old warehouse practices and new e-commerce requirements. -

.jpg?rev=c5569a1a0b934090842bf003e46a8307&la=en&h=315&w=545&hash=1E20BB461C214BCDF5168B7C201A6EC7)

Six Common Misconceptions About ASRS

While most warehouse businesses are interested in automation, many think it’s too expensive or risky to implement. When done properly, an AS/RS project can deliver massive gains in productivity and a rapid return on investment. Here are some common misconceptions about AS/RS. -

Improve Your Productivity With Parts Picking Automation: Part 1 - Labor

This five-part series looks at ways to improve the productivity of your operation using automated solutions. Part 1 - Labor Savings -

Improve Your Warehouse Profitability With Picking Automation: Part 2 – Floor Space

This five-part series looks at ways to improve your picking process using automated solutions. Part 2 - Maximize space -

Improve Your Warehouse Profitability With Picking Automation: Part 3 – Increase Parts Picking Speed

This five part series looks at ways to improve your picking process using automated solutions. Part 3 - Increase Picking Speed -

Improve Your Warehouse Profitability With Parts Picking Automation: Part 4 – Improve Ergonomics

This five part series looks at each of the ways that automating your picking processes can improve your productivity and reduce costs. -

Improve Your Warehouse Profitability With Picking Automation: Part 5 – Mispick Elimination

This five-part series looks at each of the ways that automating your picking processes can improve your productivity and reduce costs. -

Maximize Your Warehouse Utilization With Radioshuttle

Why add a pallet shuttle system to your warehouse? Find out about the features and benefits of Raymond's Radioshuttle. -

How To Avoid 5 Costly Conveyor System Mistakes

Companies depend on their conveyor systems to keep their operation running. That's why it is so important to prevent a prolonged outage. Here are 5 ways to avoid costly mistakes. -

Is It Time To Upgrade Your Order Picking System?

Advanced new technologies for batch picking and multi-order picking give warehouse operators the opportunity to eliminate errors, reduce costs, and greatly enhance productivity. But which technologies will give you the biggest bang for your buck? -

Implementing a Shuttle System In Your Warehouse

Radioshuttle is a semi-automated storage and retrieval system that helps you maximize the use of your existing warehouse space. It allows you to maintain optimal selectivity while increasing your operational efficiency. -

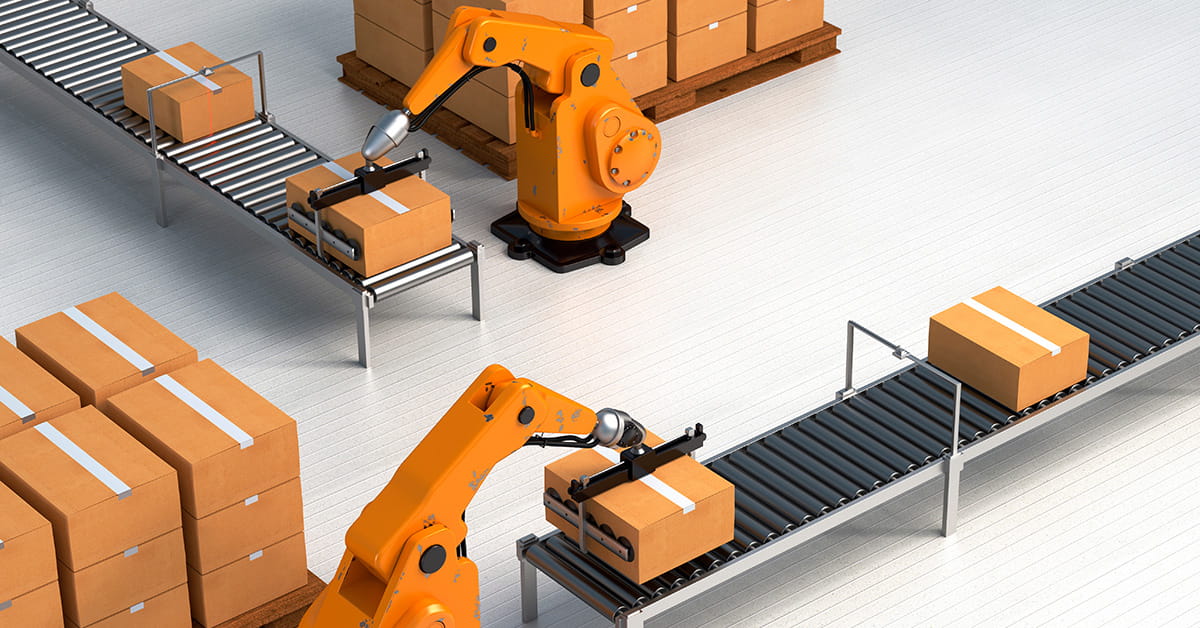

Automated Palletizing

Automated palletizing is transforming high-volume warehouse operations by enhancing efficiency, precision, and safety. These systems—ranging from conventional palletizers to advanced robotic solutions—streamline the stacking and storage process, reducing errors and increasing throughput. -

How To Gain Massive Efficiencies In Order Picking

While high tech solutions can reduce pick errors by up to 50%, only about 20% of U.S. warehouses use advanced solutions like voice directed or pick to light systems. Learn about the latest picking technologies and how they can benefit your operation. -

E-commerce Is Driving New Automation Technologies

As online sales have increased, so has the demand for warehouse automation, which is changing the way businesses handle order fulfillment. -

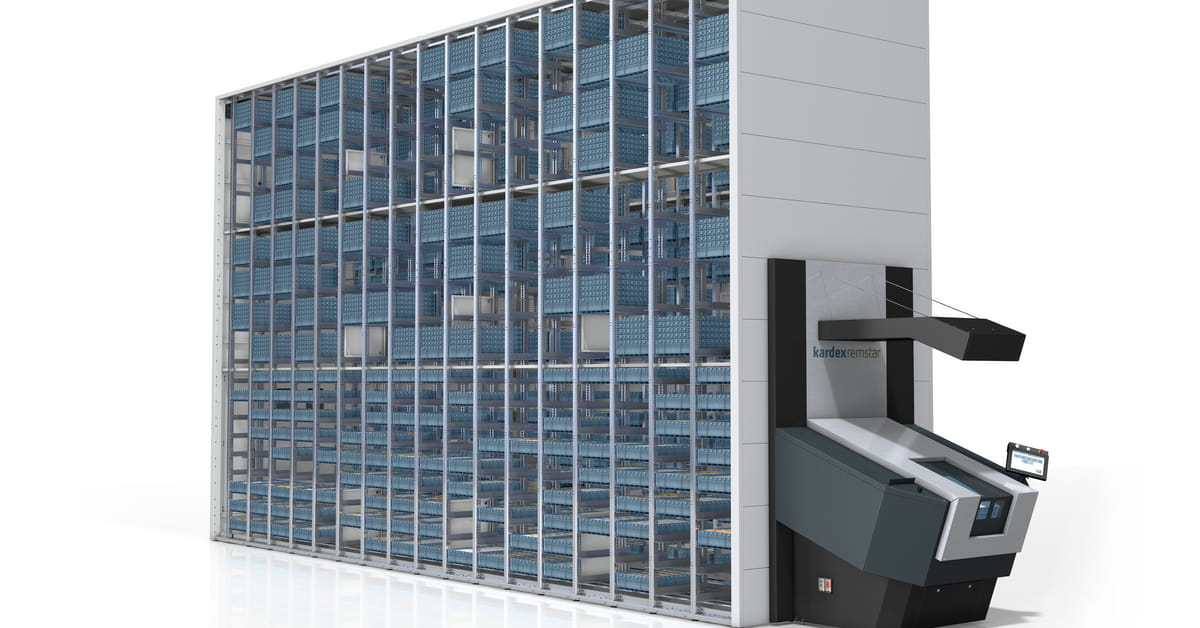

Goods To Person Automation

Many fulfillment operators have turned to Goods-to-Person (GTP) systems to meet rising demand. -

Bin And Tote Systems

In contrast to shelf based picking systems, bin based systems deliver a bin or tote of products to the operator as opposed to an entire shelf or tray. -

Robotic Delivery Systems

Modern robotic delivery solutions are taking storage technology to an entirely new level. -

5 Reasons You Should Be Using AS/RS

AS/RS systems have many advantages over traditional rack and shelving configurations. -

Powered Conveyors vs Gravity Conveyors: Which Do You Need?

How do you know what type of conveyor system you need? To start, you’ll need to understand the primary categories of conveyors and the key differences between them. -

4 Signs It’s Time To Introduce AGVs

AGVs are a perfect entry point for automation because they are easily implemented and can start generating a positive return on investment from day one. -

When Should You Replace Your Conveyor System?

Sometimes it's hard to know when to replace a conveyor instead of repair it. Here are some guidelines to follow. -

How AMRs Can Transform Your Warehouse

Autonomous mobile robots (AMR) are becoming increasingly popular in many materials handling operations, as they provide a reliable way to automate and streamline processes, boost productivity, and reduce costs. -

Cobots In The Warehouse

In this blog post, we'll explore the different ways cobots are used in warehouses, and discuss the benefits they bring to the warehouse environment. -

Locus Robotics Order Picking Solutions

Experience a revolution in warehouse operations with Locus Robotics' cutting-edge order picking solutions, enhancing efficiency, collaboration, and adaptability in the modern world of order fulfillment. -

Revolutionizing Warehouse Operations: The Power of Industrial Robotics and Automation

The adoption of robotic material handling solutions has emerged as a game-changer, offering a myriad of benefits that extend far beyond mere automation. -

Micro Fulfillment Centers

In e-commerce, businesses are turning to small, highly automated facilities that are closer to their customers. -

Warehouse Drones

Modern warehouses are turning to drones as a transformative tool in inventory management. These unmanned aerial vehicles, equipped with advanced sensors and imaging technology, can rapidly scan barcodes and RFID tags, inspect hard-to-reach storage areas, and provide real-time stock updates. -

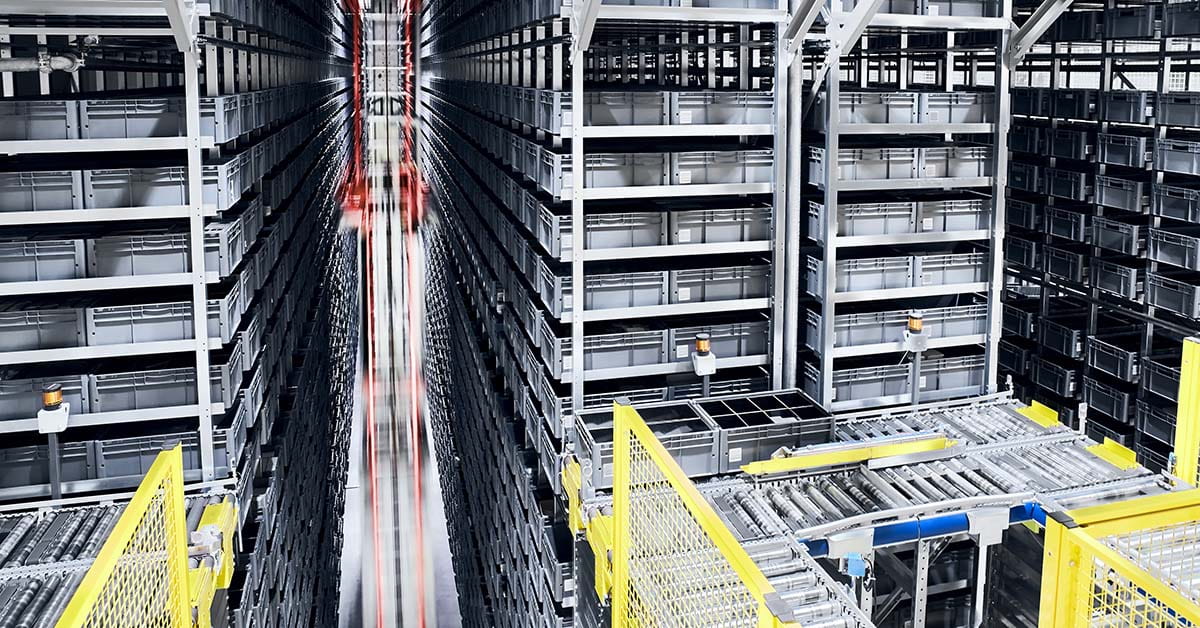

Mini-Load vs. Unit-Load

Automated Storage and Retrieval Systems (AS/RS) are transforming warehouse operations by maximizing space, boosting efficiency, and reducing labor costs. However, not all AS/RS solutions are alike. The article distinguishes between two prevalent systems: Mini-Load and Unit-Load. -

7 Trends

The material handling industry is rapidly advancing in 2025 with increased automation, sustainability initiatives, and efficiency-driven innovations. Trends like autonomous mobile robots, green forklifts, AI-powered warehouse automation, digital twins, and ergonomic solutions are transforming operations, helping businesses stay competitive in a dynamic supply chain landscape. -

Automation for E-Com

E-commerce warehouses must embrace automation to keep up with rising consumer expectations for speed and accuracy. From robotic picking systems to AI-driven inventory management, automated solutions improve efficiency, reduce errors, and help businesses scale competitively. -

Small Parcel Solutions

Small parcel automation is transforming e-commerce warehouses by integrating packing, labeling, document insertion, and sortation systems for greater efficiency and accuracy. Leveraging real-time data and AI-driven solutions, these technologies reduce errors, optimize costs, and enhance the speed of order fulfillment. -

Warehouse Automation Economics

Rising labor costs and staffing shortages are driving warehouses to adopt automation—delivering rapid ROI, improved efficiency, and long-term competitive advantage. -

Evaluating Automation ROI: A Framework for Small- to Mid-Sized Operations

A practical framework to determine whether warehouse automation will deliver real ROI for small- to mid-sized operations — or whether manual processes still make more financial sense. -

Retrofitting Older Warehouses for Automation

A deep dive into the structural, electrical, and safety challenges of retrofitting older warehouses for automation — and the best practices that keep projects on time and on budget.

Rack and Mezzanines

-

The Many Benefits of Warehouse Mezzanines

If your operation is about to outgrow your existing warehouse space, it may be time to build a mezzanine level. Raymond West is here to help you weight your options. -

Why Regular Pallet Rack Inspections Are A Must

Damaged or improperly installed racking can lead to inventory loss, property damage, legal action and even injury. Regular inspections are necessary to ensure the safety of your team and warehouse. Here is what you need to know. -

Storage Solutions: Cantilever Rack

Cantilever rack is the perfect solution for storing large, long or odd sized items like carpet rolls, plywood or steel. It allows you to store bulky items more efficiently and in far greater quantities. -

Configuring & Measuring Pallet Racks: What You Need To Know

If you're considering adding or replacing rack, knowing what factors to consider and the right way to measure pallet racks is crucial. Here's a handy guide to get you up to speed. -

Boost Efficiency With Pallet Flow Rack

Pallet flow rack may be an excellent way to make meaningful improvements to your warehouse efficiency. -

What is Pallet Rack Flue Space?

Fire safety is a top concern for many material handling organizations. Maintaining correct flue space between your racks can help slow the spread of fire, should one occur in your warehouse. -

Can You Use Pallet Rack Components From Different Manufacturers?

As companies relocate, expand or reconfigure their warehouse spaces, one question that often comes up is whether they can mix and match components from different pallet rack manufacturers. -

Modular Offices Are Not Just For Office Space

Modular office systems can add noise shielded, protected, climate controlled space to just about any industrial building. -

Paper Pallets? They’re Stronger and Lighter Than Wood.

Although wooden pallets are the de facto standard in most of the supply chain, corrugated paper pallets offer some surprising advantages that many businesses may not know about. -

How Much Rack Damage Is Too Much Damage?

How do you know when racks need to be unloaded and repaired, or completely torn down and replaced? There are actually some industry guidelines that you can go by, set by the Rack Manufacturer’s Institute (RMI). -

Reduce Pallet Costs With Slip Sheets

Many material handling operations are starting to use slip sheets in place of pallets to save money and increase efficiency. -

Rack Repair

Raymond West offers certified Damotech pallet rack repair for warehouses and industrial clients. -

Forklift Aisle Minimums

Calculating the minimum aisle width is an important step in determining which forklifts to consider purchasing. -

Is Your Warehouse Lighting Up To The Job?

Proper lighting in your warehouse can help you improve productivity, enhance safety and reduce energy costs. -

Wire Decking

Wire decking is superior to plywood in many ways, and a small investment up front can pay big dividends in the future. -

What Kind of Industrial Shelving Do I Need?

Beyond pallet rack, there are many different types of shelving for storage and industrial applications. -

8 Tips For Executing A Flawless Warehouse Move

Here are eight tips from the material handling experts at Raymond West to help your warehouse move go a little bit smoother. -

Here's Why You Might Need A Mezzanine

Mezzanines can be used for a wide range of purposes, and they can frequently offer a rapid return on investment. -

Pallet Rack Anchors

Anchoring your racks is not merely a suggestion, the Rack Manufacturers Institute (RMI) guidelines have stringent specifications on base plates, anchors and surfaces. -

What Is A High Piled Storage Permit, And When Do You Need One?

A high piled storage permit is necessary for fire safety and regulation compliance in warehouses storing combustible materials stacked high on vertical storage racks. -

Can Your Concrete Floor Support A Mezzanine?

Determine whether your concrete floor can support a mezzanine system, including factors like concrete thickness, load capacity, platform load rating, and column spacing; and what to do if your floor won't support it. -

Is It A Mezzanine, Or A Work Platform? Words Matter.

Learn the difference between an industrial mezzanine and a work platform, and why calling your elevated platform a mezzanine could cost you money in taxes, code compliance, and depreciation. -

Maximizing Efficiency: The Benefits of Implementing a Carton Flow System in Your Business

Boost order fulfillment efficiency with a Carton Flow System. Explore benefits and choose the right solution for your business at Raymond West. -

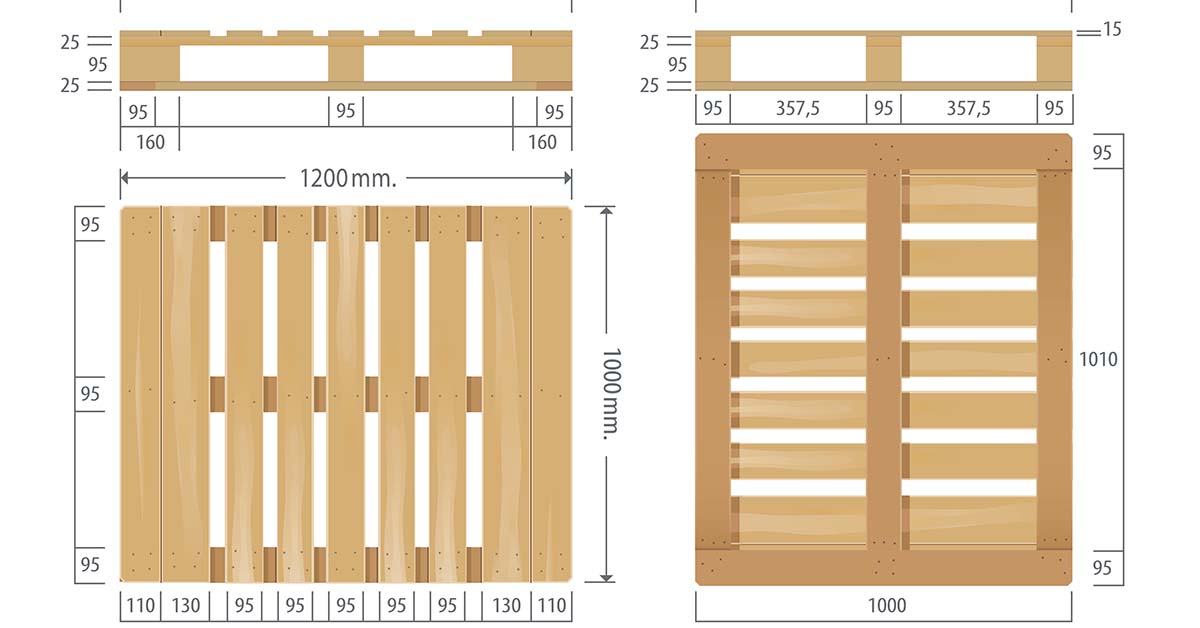

North American Pallet Standards: Ensuring Efficiency and Safety in Material Handling

Uncover the essential role of standardized pallets in North American logistics. Explore guidelines, compliance, and efficiency for improved material handling.

Dock and Door Equipment, Service

-

Loading Dock Equipment Safety Checklist

Your loading dock is the busiest part of your warehouse which can result in a variety of potential safety issues. Use this checklist to perform routine equipment safety inspections. -

Five Top Tips for Loading Dock Safety

Your loading dock is one of the busiest areas of your warehouse, it's also one of the most dangerous. Here are a few safety tips to make your dock a safer place. -

Do you need dock seals or shelters? Part 1: Seals

What are the primary applications for dock seals and shelters? In this two part series, we’ll walk you through determining the best configuration for your facility. -

Do you need dock seals or shelters? Part 2: Shelters

What are the primary applications for dock seals and shelters? In this two part series, we’ll walk you through determining the best configuration for your facility. -

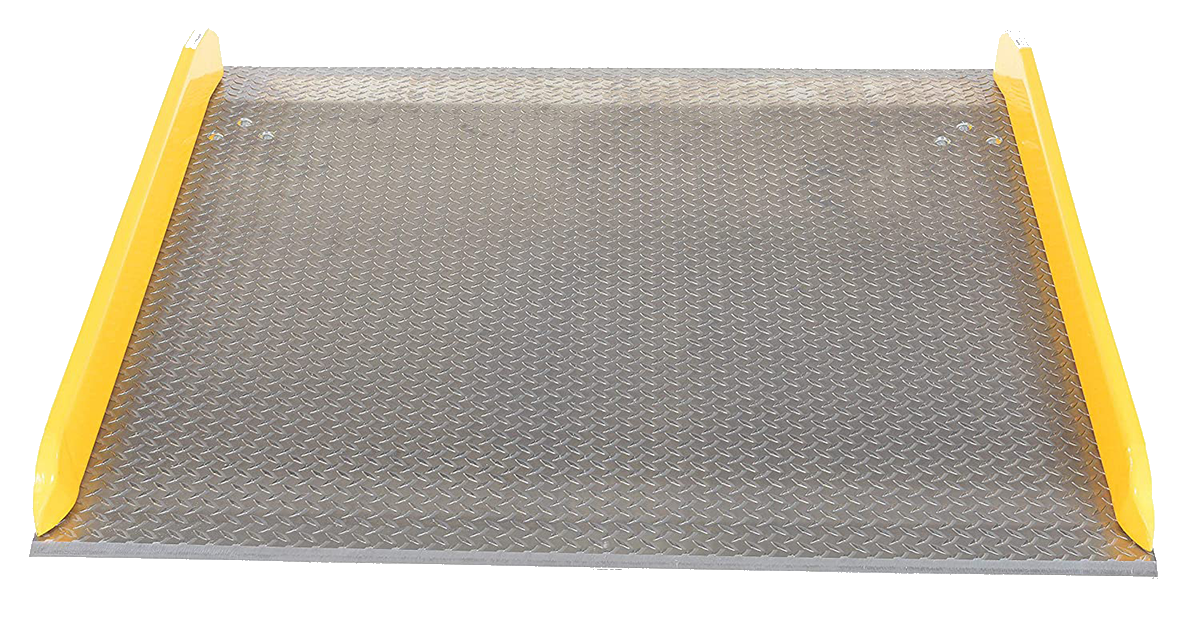

When is the Right Time to Replace Your Dockboard?

Although dockboards are extremely durable, even the most well constructed units must periodically be replaced because of the wear and tear they are exposed to on a daily basis. -

Modernize Your Dock And Improve Your Bottom Line

Here's how to use the latest technology to improve safety, increase efficiency and make your dock the cornerstone of your operation. -

4 Ways To Improve Your Loading Dock Efficiency

In order for warehouses to remain competitive and efficient, it's important that loading dock processes are consistently optimized for maximum performance. -

Unlocking Productivity: How High-Speed Doors Can Benefit Industrial Operations

Discover how high-speed roll-up doors can benefit warehousing and logistics operations by optimizing efficiency, enhancing productivity, and improving energy efficiency. -

Ramping Up Productivity: How Yard Ramps Can Benefit Your Business

Discover how high-speed roll-up doors can benefit warehousing and logistics operations by optimizing efficiency, enhancing productivity, and improving energy efficiency. -

How to Properly Maintain Overhead Doors on Your Warehouse Loading Dock

Ensure the seamless flow of goods in and out of your facility by mastering the art of warehouse loading dock overhead door maintenance. -

Using iDock Control Systems To Transform Your Loading Dock Operations

Revolutionize your loading dock operations with the power of iDock control systems, seamlessly integrating technology, automation, and safety to create a well-coordinated and efficient environment for modern logistical needs. -

.jpg?rev=62f88d95db8f4e5f86e2c51ac73f829b&la=en&h=628&w=1200&hash=88329C86D0BDEB2882077AA6AE8FD9FC)

What You Should Know About Loading Dock Trailer Restraints

Learn the basics of working with trailer restraints on your loading dock. -

A Simple Guide to Loading Dock Bumpers for Warehouse Operations

A comprehensive guide to loading dock bumpers and their applications on your dock. -

Loading Dock Security

The loading dock is a vital hub for warehouse operations, but it’s also a prime target for security threats. Strengthening dock security not only protects inventory but also enhances operational resilience, employee safety, and customer trust. -

Dock Locks

Dock locks, or vehicle restraints, are essential for warehouse safety, preventing trailer creep, premature departure, and unintentional truck movement during loading and unloading. By securing trailers in place, these systems reduce accidents, protect workers, enhance efficiency, and help facilities comply with safety regulations. -

Dock Safety Lights

Loading dock safety lights play a crucial role in preventing accidents by improving visibility and communication between workers, forklift operators, and truck drivers. Investing in strategically placed LED dock lights enhances efficiency, reduces human error, and provides a cost-effective solution for warehouse safety.

Optimization-iWAREHOUSE

-

Enhancing Forklift Operations with Raymond's iWarehouse Integrated Tether System

The iWarehouse Integrated Tether System is designed to reinforce forklift operator training and best practices. -

Material Handling AI

Artificial Intelligence (AI) is set to revolutionize the warehouse and material handling industry, transforming operations, boosting efficiency, and significantly reducing costs. -

Applying OSHA Fall Protection Rules in Your Warehouse

Navigating OSHA's stringent fall protection regulations in warehouses is critical for safeguarding employees from one of the leading causes of workplace injuries and fatalities, emphasizing the need for comprehensive compliance plans and rigorous safety measures. -

Risk Assessment

Conducting a warehouse risk assessment is one of the best things you can do for maintaining a safe working environment, ensuring regulatory compliance, and preventing costly accidents. -

Warehouse Worker Fatigue Might Be A Bigger Problem Thank You Think

According to the National Safety Council (NSC), worker fatigue costs employers in the US an estimated $136B in health-related lost productivity annually. -

Monitoring and Reducing Forklift Impacts

Although most forklift impacts are minor, some can cause real damage. By tracking forklift impacts in real time you can improve operator accountability while making your facility a safer place to work. -

Using Telematics To Right-Size Your Lift Truck Fleet

Telematics systems can help you right-size your lift truck fleet, as well as zero in on exactly what types of trucks you’ll need to maximize efficiency -

Optimize Before You Automate

Many organizations make changes to their operation based on assumptions, not hard data. Warehouse optimization provides the data you need to build solid ROI models. -

The Many Benefits of Using an Integrated Material Handling Solutions Provider

With over 400 technicians and 19 locations, Raymond West serves the Western United States from Alaska all the way to Arizona. With our network of other Raymond dealers across the country, we can service nearly any location in the country. -

5 Smart Tips For Warehouse Energy Cost Savings

From making small adjustments to larger investments in technology, we’ll take a look at how warehouses can operate more efficiently while also cutting down on energy expenses. -

Designing Warehouses For Improved Ergonomics

To help improve the workplace environment, warehouse ergonomics can be used to reduce the risk of injury and make the workplace more comfortable and efficient. -

Some Important Fire Safety Practices For Your Warehouse

To help warehouse operators stay safe and prepared, here are some important fire safety tips to keep in mind. -

How To Keep Your Conveyors Running Flawlessly

Conveyor systems are an essential part of many industrial operations. From preventative maintenance to regular inspection, cleaning and lubrication, and even keeping spare parts on hand, we'll cover everything you need to know to keep your conveyors running flawlessly. -

How Can Pick-To-Light Benefit Your Business?

Advantages of pick-to-light systems in warehouse automation include increased accuracy, productivity, and cost savings, as well as real-time inventory tracking and easy integration with other automation systems. -

The Top 3 Benefits Of A Voice Picking System

Discover how voice picking systems can streamline warehouse operations and increase productivity, accuracy, and worker morale with clear and concise instructions. -

10 Tips For Warehouse Loss Prevention

Warehouse loss prevention is a critical aspect of managing any distribution or storage facility. -

Ensure Workplace Safety with Warehouse PPE

Discover crucial Personal Protective Equipment (PPE) for warehouse workers' safety. From helmets to high-visibility gear, ensure a secure work environment. -

Sustainable Material Handling: Implementing Eco-friendly Practices in Your Operations

Elevate efficiency and reduce costs. Optimize warehouse, boost energy efficiency, recycle, and adopt eco-friendly packaging for a sustainable future. -

Enhancing Warehouse Efficiency: Exploring the Uses and Benefits of iWarehouse

Discover the future of warehouse efficiency with iWarehouse Fleet Optimization. Real-time monitoring, operator tracking, and data-driven decisions for enhanced safety and productivity. -

Using Raymond Intralogistics Solutions to Gain A Competitive Advantage

Raymond is reshaping the way businesses handle material goods within their facilities with a comprehensive intralogistics solutions. -

Enhancing Warehouse Safety with Raymond's In-Aisle Detection System

The In Aisle Detection System is designed to alert operators when objects are detected in the truck's path, bringing the truck to a controlled stop. -

Defining Intralogistics: Key Concepts for Modern Material Handling Operations

Intralogistics is more than just a buzzword, but only if you have the right partner to help you implement it. -

Preparing Your Warehouse for Natural Disasters

Proper preparation can minimize damage, ensure employee safety, and maintain business continuity. -

Inventory Management Best Practices

Effective inventory management is essential for warehouse managers to ensure smooth operations, minimize costs, and prevent disruptions. -

Organizing Warehouse

Warehouse organization is key to maintaining a streamlined, safe, and productive environment. -

Belt vs Roller

Automated palletizing is transforming high-volume warehouse operations by enhancing efficiency, precision, and safety. These systems—ranging from conventional palletizers to advanced robotic solutions—streamline the stacking and storage process, reducing errors and increasing throughput. -

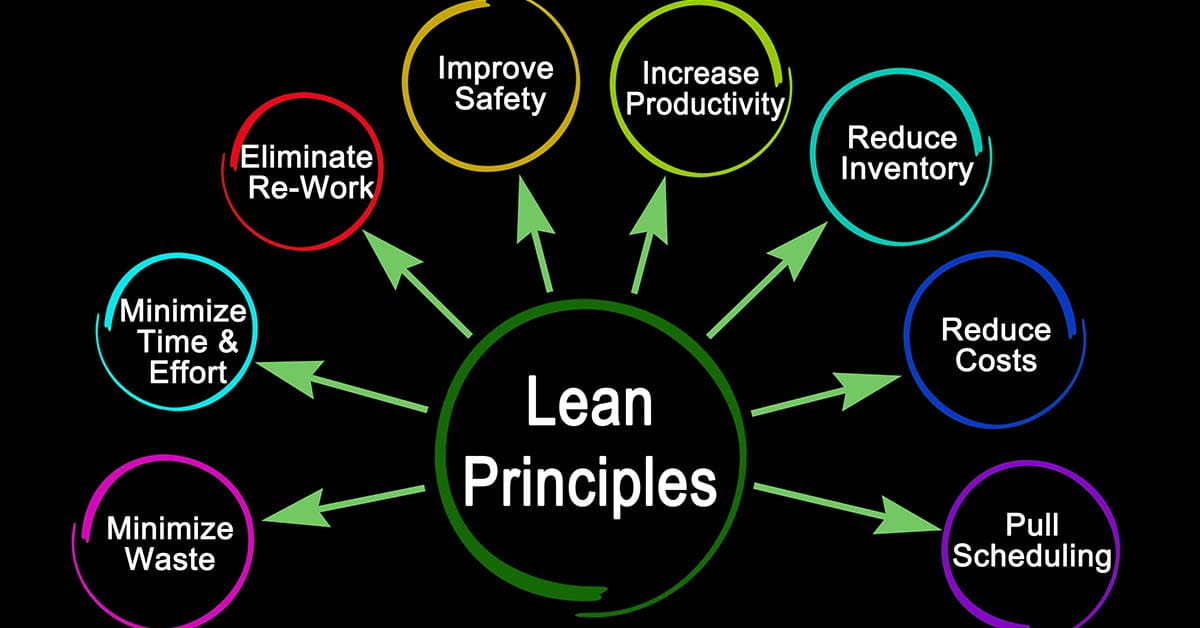

Lean Principles

Warehouses are fast-paced environments, but hidden inefficiencies can slow operations and drain profits. Embracing Lean isn’t just about cutting costs—it’s about creating a smarter, more agile warehouse that benefits both employees and the bottom line. -

Predictive Maintenance

Predictive forklift maintenance can significantly reduce downtime and costs in warehouses. Raymond’s iTrack system leverages real-time data and analytics to anticipate maintenance needs, streamline repairs, and optimize fleet performance for improved efficiency and reliability. -

ObjectSense

The iWAREHOUSE ObjectSense Detection and Notification System enhances warehouse safety by using lidar-scanning technology to adapt detection fields based on forklift speed and steer angle, reducing collision risks. By integrating real-time data and analytics, it not only prevents accidents but also provides actionable insights for optimizing training, maintenance, and traffic flow. -

Using AI To Optimize Your Warehouse Layout Design

AI-driven warehouse layout design boosts efficiency, reduces labor costs, and adapts in real time to maximize space, speed, and accuracy across your operations. -

Beyond Telematics: Using Data Analytics to Right-Size Your Material Handling Fleet

Go beyond telematics with advanced data analytics to right-size your material handling fleet, cut costs, boost utilization, and maximize warehouse efficiency. -

Warehouse KPI Dashboard: The 12 Metrics Every Operations Manager Should Track

Go beyond telematics with advanced data analytics to right-size your material handling fleet, cut costs, boost utilization, and maximize warehouse efficiency. -

Using Wearable Technology for Enhanced Warehouse Efficiency

Discover how smart glasses, voice-picking headsets, and wearable scanners can boost accuracy, speed up training, and improve safety—transforming your existing warehouse into a more efficient, hands-free operation. -

Implementing Labor Management Systems for Improved Productivity

Learn how modern Labor Management Systems uncover missing time, optimize indirect work, and boost direct labor productivity—turning workforce visibility into one of the highest-ROI opportunities in today’s warehouse operations. -

Commercial Electric Utility Vehicles for Indoor Manufacturing

Evaluate your facility's transportation needs and learn about solutions that integrate seamlessly with your existing electric fleet. -

Why More Warehouses Are Adding Industrial Cleaning Equipment to Their Fleet Management Programs

Discover how how commercial-grade cleaning solutions integrate with your material handling fleet management strategy.

Finance & Leasing

-

The Smart Money Move: Why Leasing Material Handling Equipment Often Beats Buying Outright

Leasing material handling equipment boosts cash flow, reduces maintenance costs, and keeps your operation current with the latest technology and tax advantages. -

10 Reasons to Lease Your Material Handling Equipment

If you are considering buying material handling equipment, consider the advantages of leasing vs. purchasing -

2019 Accounting Rule Changes Seriously Impact Equipment Leases

In 2019, changes to GAAP rules moved operating leases to the balance sheet. What does that mean for your lift truck operation? Plenty. -

Leasing Tips For Today’s Material Handling Operations

When you’re leasing forklifts or other equipment, having a partner that has the flexibility to build individual programs around your unique business requirements can make a real difference to your bottom line. -

Why Owning Your Forklifts Is Sometimes Better Than Renting

While renting or leasing your forklifts can make a lot of sense financially, there are many situations where it is simply more beneficial to own them outright.

Contact Us

To get more information on any of the topics mentioned here, please get in touch with us by filling out the form below. A Raymond West representative will contact you within one business day.