inVia Robotics | San Diego

Raymond West helps warehouses overcome rising labor costs and delivery pressures with intelligent automation solutions from inVia Robotics. With locations across 8 Western states, we have a location near you. Call us today at (858) 679-1800.

Meeting Modern Warehouse Challenges

Traditional warehouse operations have difficulty with today's e-commerce demands. As opposed to conventional automation demanding substantial facility redesigns and capital investments, inVia Robotics revolutionized the industry with their RaaS model. This approach allows warehouses of all sizes to gain enterprise-level automation without traditional barriers.How inVia's System Works

The inVia system consists of three integrated components designed to optimize warehouse operations. inVia Logic AI-powered warehouse execution system acts as the intelligent brain, coordinating workflows and making over one million daily decisions to ensure SLA compliance. This software assesses order profiles, workforce performance, and inventory data to dynamically assign tasks. inVia Picker autonomous mobile robots handle actual automation, with compact dimensions and forty-pound payload capacity. They operate with industrial precision, using suction cup technology while traversing aisles at speeds approaching 5 mph. In contrast to traditional AMRs depending on human workers, inVia Pickers independently build dynamic inVia PickerWalls for offshift operations. The Robotics Operations Center (ROC) offers 24/7 support plus monitoring. This remote system uses live simulations to proactively spot potential bottlenecks before disrupting operations.Proven Results Across Industries

Real-world implementations demonstrate inVia's impact. SICK Sensor Intelligence realized a remarkable 10X increase in pick rates, rising from 75 UPH to 764 UPH while securing full ROI within six months. One customer tripled productivity while cutting labor costs by 70%. An additional customer reduced their labor costs by 65% and boosted productivity sixfold. These results come from the software-first approach of inVia. As opposed to beginning with expensive hardware, inVia Logic streamlines existing workflows first, generating immediate two to three times productivity gains before deploying robots for 4-5X overall improvements.Flexible Implementation Without Disruption

Implementation poses challenges for warehouse operators who must avoid disruptions. inVia addresses this through a streamlined five-step process implementing automation in weeks, not months. The system connects with existing WMS through APIs and adapts to current layouts, eliminating infrastructure modifications. Twin IQ intelligent simulation technology decreases implementation risks by developing digital twins of warehouse operations. This tool empowers managers to assess scenarios and refine workflows before physical changes, providing maximum day-one efficiency.Scalable Solutions for Growing Operations

inVia's phased approach supports different automation stages. Operations begin with software-only solutions, move to automated labor with robotic picking, and in the end achieve fully automated capabilities. This flexibility enables growing automation investments in parallel with growth while maintaining continuity. The monthly subscription model aligns costs with usage, eliminating large capital expenditures while offering predictable expenses. inVia operates, maintains, and owns all equipment throughout service contracts, reducing internal overhead.Your Path to Advanced Automation

For San Diego-based warehouse managers prepared to transform operations, inVia Robotics represents tested technology with measurable results. Whether handling labor shortages, facing fulfillment pressure, or seeking space optimization, the intelligent automation offers a clear path forward. Get in touch with Raymond West today to find out how inVia Robotics solutions can improve your warehouse operations and deliver the advantages your business demands in San Diego's dynamic marketplace.Raymond West's San Diego facility serves all of San Diego County, including Carlsbad, Chula Vista, Downtown, El Cajon, Escondido, Fenton Carroll Canyon, Grantville, Kearney Mesa, Levanto, Morena, National City, Oceanside, Otay, Otay Mesa, Poway, San Marcos, Santee, Sorrento Mesa, Spring Valley, Vista and all surrounding areas.

Raymond West | San Diego Material Handling Equipment Supplier

8221 Arjons Dr # B2

San Diego, CA 92126

(858) 679-1800

You May Also Like:

Robotic Palletizers | San Diego

Robotic palletizers are a flexible and cost-effective solution for warehouses to improve efficiency, reduce labor costs, and enhance safety by handling a wide range of products at high speeds with higher accuracy and scalability.

Learn More

Warehouse Robotics

Warehouse Robotics can change the economics of your warehouse. Raymond West is among the top warehouse automation suppliers in the Western US. Give us a call today!

Learn More

Locus Robotics | San Diego

Raymond West Intralogistics Solutions is an authorized distributor of advanced automation solutions from Locus Robotics.

Learn More

Cobot Systems

Raymond West offers a full suite of warehouse robotics solutions, including cobot systems.

Learn More

Movu Robotics Solutions | San Diego

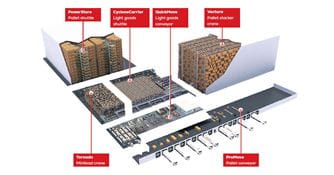

Raymond West offers sales and service for a full suite of warehouse robotics solutions from Movu and other leading manufacturers.

Learn More

Swisslog

Raymond West offers a full suite of warehouse automation solutions from Swisslog and other leading manufacturers.

Learn More