Burden Carrier | Ontario

Discover how burden carriers can boost efficiency, safety, and productivity in your warehouse operations. Raymond West offers electric burden carrier solutions from top manufacturers. Call us today at (909) 930-9399.

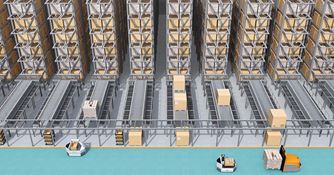

In fast-paced warehouse facilities, managers continually look for ways to optimize operations and maximize productivity. While lift trucks and conveyor systems frequently receive primary focus, a significant number of operations overlook the real-world benefits of burden carriers: compact, versatile vehicles purpose-built for horizontal material handling.

What Are Burden Carriers?

Burden carriers are battery-powered vehicles that have flat cargo decks. As opposed to forklifts, which specialize in vertical lifting, burden carriers are used in rapidly moving heavy or bulky loads across expansive warehouse facilities. Engineered for maneuverability, they can maneuver through narrow aisles and busy environments with ease, making them particularly well-suited for urban warehouses where space is at a premium.

Standard burden carriers provide impressive capabilities:

- Payloads ranging from several hundred to several thousand pounds

- Towing capacities that can exceed most pickup trucks

- Versatile configurations for hauling materials, tools, or people

Key Advantages for Warehouses

1. Increased Productivity

In the dynamic logistics landscape of Lathrop, time is money. Burden carriers cut down transit times for materials, permitting operators to haul many items in one trip while decreasing reliance on slower manual methods. Through significantly less walking and fewer trips required, workers can focus on value-added activities.

2. Optimal Use of Space

Escalating real estate costs make every square foot in Lathrop warehouses count. The space-efficient design and agile handling of burden carriers allow you to use narrow aisles and crowded docks more effectively, increasing storage density without reducing safety or productivity.

3. Budget-Friendly Solution

As opposed to investing in additional forklifts, which could be excessive for some tasks, burden carriers represent a cost-efficient alternative that's specifically designed for horizontal movement. They're also typically simpler to keep operational, with electric power resulting in fewer moving parts and lower operating costs.

4. Greener, Safer Operations

With electric power comes zero carbon emissions and quieter operation, creating a better environment for your team. Lower operating speeds and enhanced visibility minimize collision risks, supporting a strong safety culture.

Typical Applications

- Material Transport: Haul parts, packaging, or finished goods rapidly between storage, docks, and production areas.

- Order Picking: Streamline order fulfillment by permitting pickers to collect and load items directly onto the carrier.

- Personnel Transport: Move supervisors or maintenance staff across large sites to minimize transit time and decrease fatigue.

Implementation Insights

Success with burden carriers begins with a clear understanding of your warehouse's particular needs. Evaluate:

- Load weight and size

- Aisle width and turning clearances

- Required travel distances

Integration is straightforward, but preparing charging stations and operator training will help improve uptime and ROI.

Why Consider Burden Carriers Now?

Labor shortages and rising operational costs are fueling the need for more efficient solutions in Lathrop warehouses. Burden carriers offer a versatile and affordable way to move people and materials, helping your team stay efficient and competitive in a formidable market.

Ready to explore how burden carriers can transform your operation?

Reach out to Raymond West to discuss your unique requirements. Our team knows the challenges encountered by warehouse and logistics operators and can suggest the best burden carrier solutions to support your goals.

Raymond West's Ontario, California facility serves parts of Los Angeles County and San Bernardino County, including Ontario, Fontana, Rancho Cucamonga, Upland, La Verne, San Dimas, Covina, West Covina, Pomona, Diamond Bar, Rowland Heights, Chino, Norco, Eastvale, Corona, Jurupa Valley, San Bernardino, Rialto and all surrounding areas.

Raymond West | Ontario California Material Handling Equipment Supplier

4602 E Brickell St

Ontario, CA 91761

(909) 930-9399

You May Also Like:

High Speed Doors | Ontario

High speed doors offer many advantages in warehousing, cold storage and manufacturing operations.

Learn More

HVLS Fans | Ontario, CA

For plants or warehouses, HVLS fans can have a significant influence on both heating and cooling costs and worker morale.

Learn More

Yard Ramps | Ontario

Raymond West supplies high quality yard ramps for warehouse and industrial use.

Learn More

Industrial Workstations | Ontario

Raymond West supplies top quality workstations for warehouse and industrial applications. We offer a full line of equipment to warehouse operators throughout the West.

Learn More

Industrial Lift Tables | Ontario

Industrial lift tables are versatile pieces of warehouse equipment, allowing the handling of heavy loads, streamlining processes, and improving worker ergonomics.

Learn More

Warehouse Equipment | Ontario

Raymond West offers a broad range of warehouse equipment from top manufacturers.

Learn More

Stock Chaser | Ontario

Discover how stock chasers can dramatically improve efficiency, safety, and productivity in your warehouse operations.

Learn More