Pallet Jacks | Reno / Sparks, NV

Raymond West is a Reno / Sparks supplier of new and used electric and manual pallet jacks.

We are backed by one of the largest service and parts operations in Nevada.

Call us today at 775-356-8383

Anytime you are considering the purchase of pallet jacks, it's useful to examine the positive points and some of the shortcomings of different kinds of pallet equipment.

Certainly, the fundamental purpose of a pallet truck is to propel pallets around a distribution center, loading dock or other enterprise where pallets need to be moved.

That being said, based on the size of your facility, the weight of pallets being transferred, the rate of use, and various other considerations, you will most likely wish to get a more thorough understanding of which pallet trucks perform best in which environments.

The following information is a compendium of pallet jack styles, features, drawbacks and types of uses.

Hand Pallet Jacks

Non-motorized pallet jacks have been in use since 1918 and have never been modified much since that period. They are made up of a steel frame, a fork and a hydraulic pump that's actuated by forcing the handle up and down.

The operator of a hand pallet truck positions the forks under the pallet, pumps the pallet away from the floor and moves the pallet to an intended place, guiding the pallet jack with the handle.

Situations where lift height is not essential can be a good application for a non-motorized pallet jack, including retail aisles, warehouse loading docks and similar. Unlike a lift truck, they're also somewhat mobile and will fit in the back of a cargo van or truck for delivering goods. The load limit of most hand pallet jacks is around 5500 pounds.

Non-motorized pallet jacks are ideal for periodic use situations over limited distances. They are not the best option for transferring loads over more lengthy ranges, slopes or rough floor or lot surfaces. Operators have to physically push or pull the device which may be physically tiring after a short period.

Walkie Pallet Jacks

Regardless of the fact that they're about two times the size of hand pallet trucks, walkies are nonetheless comparatively small in overall size and they're exceptionally maneuverable.

Walkie pallet jacks are powered by on-board battery units. The battery generates a powered assist for driving and elevating the forks. The worker no longer needs to activate the tiller to lift the pallet, nor do they have to manually propel the load along through the warehouse.

Nevertheless, they are still known as "walkies", because the driver does still have to walk behind or alongside them.

A walkie pallet jack's highest rate of speed is moderate as compared to rider jacks, since the driver has to keep up with the truck instead of riding on it. This is in fact somewhat of a built in "safety feature", since limited speeds also minimize the consequences of collisions.

The weight capacity of most walkie pallet jacks is between 4500-6000 lbs.

Although they're more practical than manual pallet trucks, walkies have to be recharged consistently, because they are battery operated. They also call for more maintenance than non-powered pallet trucks considering that there are many more moving parts and points of possible mechanical problems.

The principal applications for walkie pallet jacks are staging areas, loading docks and short to mid-length runs.

Rider Pallet Jacks

Rider pallet trucks are similar to walkies, although they offer an additional standing platform for the user. There are few controls on rider trucks so they are reasonably straightforward to control and require very little operator training.

Users can climb aboard the platform rather than just keeping pace in the rear or on the side of the pallet truck. This means that rider jacks are a better solution for transferring pallets over greater ranges vs walkie or manual pallet trucks. They are most suitable for frequent movement over longer distances and they're used frequently in large warehouse complexes and industrial operations.

The driver platform is appropriate for quick trips, but not great for users that use them day in and day out because they are rather minimal and cause the controller to stand at a sideways angle.

Rider jacks are much heavier than walkie or manual pallet trucks, so impacts can trigger fairly serious injury and property damage. Rider pallet trucks provide minimal defense for the driver vs other options like center riders.

Center Riders

Center riders are similar to rider pallet jacks, but they're more protected for the operator and offer a more pleasant drive. The operator can stand fully to the front or to the back rather than only to the side.

Additionally, there is minimal risk for the driver, considering they are shielded by the machine frame on two sides, although they're still vulnerable to the possible risk of the lifting system.

Center riders are less maneuverable than rider pallet jacks and they are best suited for uses where the user proceeds typically in a direct path.

Center riders are typically employed in general factory operations, distribution center and beverage uses.

Where To Rent Or Buy Pallet Trucks In Reno / Sparks, Nevada

If you’d like to speak with a Raymond representative about pallet jacks, please get in touch with Raymond West, a Washoe County material handling equipment supplier serving all of Western Nevada, including: Reno, Sparks, Carson City, Minden, Gardnerville, Incline Village, Virginia City, Indian Hills, Johnson Lane, Fernley, Fallon, Dayton, Silver Springs, Spanish Springs, Yerington, Genoa and Zephyr Cove.

Raymond West | Reno / Sparks Material Handling Equipment Supplier

975 Terminal Way

Reno, NV 89502

(775) 356-8383

You May Also Like:

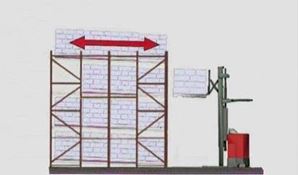

Pallet Racks & Warehouse Storage Solutions | Reno / Sparks

Raymond West offers pallet rack design, delivery, installation, service and parts throughout Western Nevada.

Learn More

Warehouse Mezzanine Systems

We offer all types of mezzanine systems and modular office components for warehouse and industrial use in Western Nevada

Learn More

Conveyor Systems

Conveyors can greatly improve the efficiency and productivity of your warehouse while reducing labor costs.

Learn More

Lektriever Vertical Carousel

We handle a full line of Kardex products, including Lektriever and Megamat vertical carousels.

Learn More